| SiC Technical Data: |

|

|

|

| Properties |

Sintered Silicon Carbide (SiSiC)

Reaction Bonded Silicon Carbide(RBSiC) |

Recrystallized Silicon

Carbide (R-SiC) |

Nitride Bonded

Silicon Carbide(NSIC ) |

| SiC % |

90~92 |

>99 |

≥75 |

| Si % |

8~10 |

0 |

0 |

| Si3N4 % |

0 |

0 |

≥23 |

| Density g/cm3 |

>3.02 |

2.65~2.75 |

2.65~2.85 |

| Porosity % |

<0.1 |

15-18 |

13-15 |

| Bending strength (20℃)Mpa |

260 |

80~100 |

160-180 |

| Bending strength (1200℃)Mpa |

280 |

90~110 |

170-180 |

| compressive strength (20℃)Mpa |

900 |

≥300 |

580 |

| Hardness Kg/mm2 |

2400 |

1800~2000 |

2000-3000 |

| Thermal Conductivity (1200℃)w.m-1.k-1 |

45 |

36 |

19.6 |

Coefficient of thermal expansion(1200℃)

α×10-6/C |

4.5 |

4.6 |

4.7 |

| Modulus of elasticity (20℃)Gpa |

330 |

280 |

170-190 |

| Maximum operation temperature ℃ |

1380 |

1650 |

1450 |

| |

|

|

|

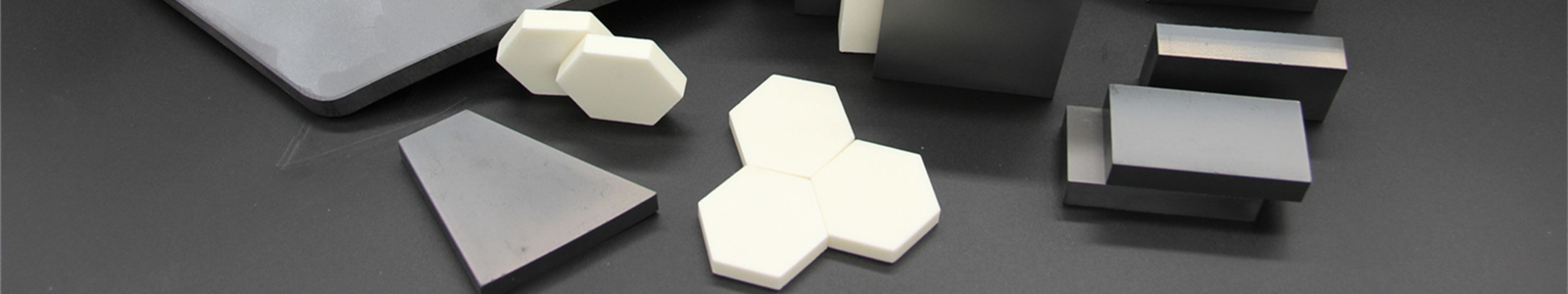

SiC Kiln Furniture Types& Application:

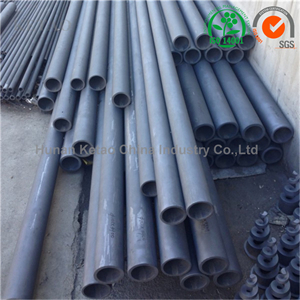

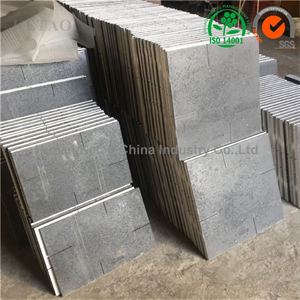

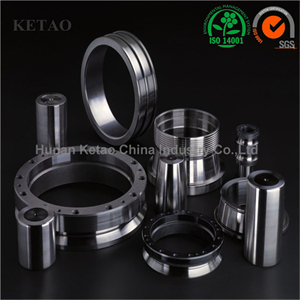

Beam/Roller Plate/Colling tube/Nozzle/Thermal tube/Structual parts/Sagger/Tableware/Sanitary Ceramic/Construction Tiles/Technical Ceramic/Electronic Ceramic/Electric Ceramic/Metallurgy/Chemical Industry |