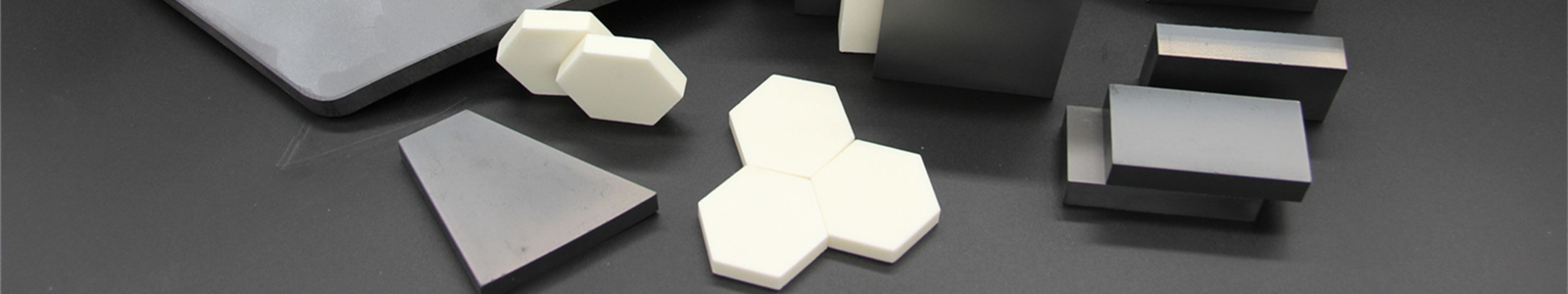

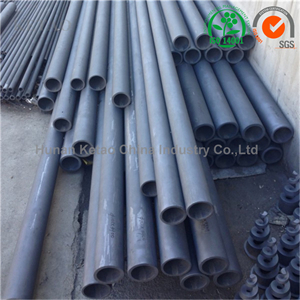

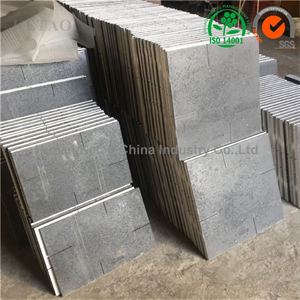

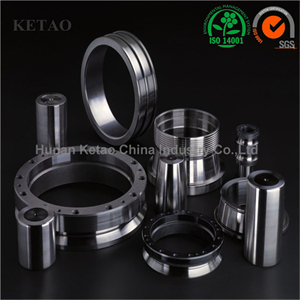

Silicon Carbide Ceramics (SiC) belong to non-oxide ceramic, it not only has excellent mechanical properties at room temperature, such as high bending strength, excellent oxidation resistance, good corrosion resistance, high wear resistance and low coefficient of friction, but also the high temperature mechanical properties (strength, creep resistance Etc.) are known to be the best of ceramic materials. Hot pressing sintering, pressureless sintering, hot isostatic pressing sintering of the material, the high temperature strength can be maintained to 1600 ℃, it is the best ceramic material for high temperature strength. Antioxidant properties are also the best of all non-oxide ceramics. Silicon carbide is formed in two ways, reaction bonding and sintering. Each forming method greatly affects the end microstructure. Reaction bonded SIC is made by infiltrating compacts made of mixtures of SiC and carbon with liquid silicon. The silicon reacts with the carbon forming more SiC which bonds the initial SiC particles. Sintered SiC is produced from pure SiC powder with non-oxide sintering aids. Conventional ceramic forming processes are used and the material is sintered in an inert atmosphere at temperatures up to 2000ºC or higher. Both forms of silicon carbide (SiC) are highly wear resistant with good mechanical properties, including high temperature strength and thermal shock resistance. Our engineers are always available to best advise you on the strengths and weaknesses of each ceramic for your particular needs.