-

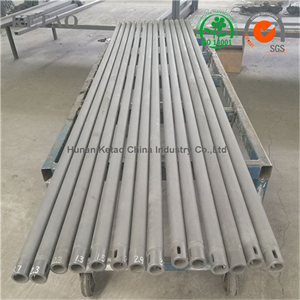

High Temperature Resistance: R-SiC exhibits excellent thermal stability and can withstand extremely high temperatures, making it suitable for applications in high-temperature environments.

-

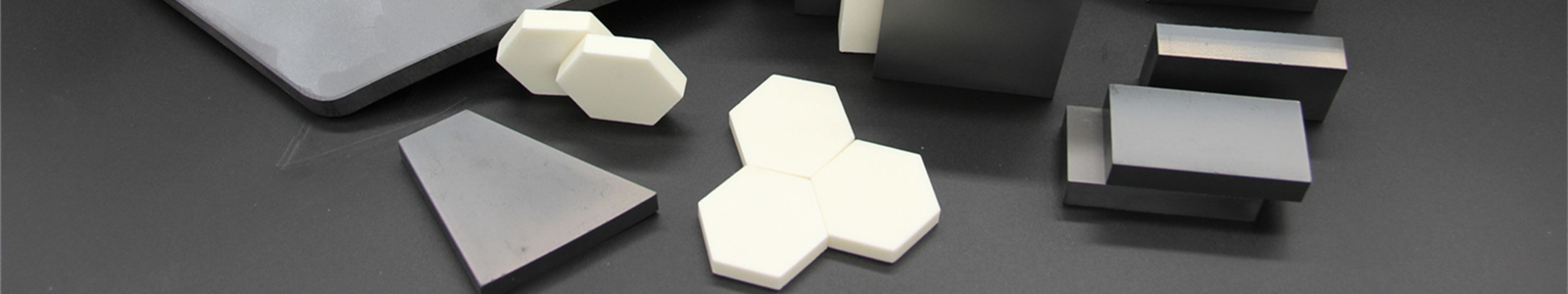

Superior Mechanical Properties: R-SiC possesses high strength, hardness, and wear resistance, allowing it to withstand demanding mechanical conditions and abrasive environments.

-

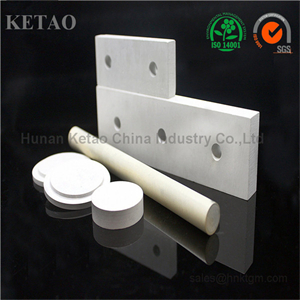

Excellent Chemical Resistance: R-SiC is highly resistant to chemical attack, making it suitable for use in corrosive environments and applications where exposure to acids, alkalis, and other aggressive chemicals is expected.

-

Low Thermal Expansion: R-SiC has a low coefficient of thermal expansion, which means it can maintain its dimensional stability even when subjected to rapid temperature changes. This property makes it ideal for applications requiring thermal shock resistance.

-

Electrical Insulation: R-SiC is an excellent electrical insulator, making it suitable for use in electrical and electronic applications that require high-temperature insulation and resistance to electrical conductivity.

-

Lightweight: Despite its exceptional strength and hardness, R-SiC is relatively lightweight compared to other ceramic materials, which can be advantageous in weight-sensitive applications.

-

Industrial Heating Systems: R-SiC is commonly used in the manufacturing of heating elements and components for high-temperature furnaces and industrial heating systems.

-

Kiln Furniture: R-SiC is widely employed in the production of kiln furniture, such as shelves, supports, and setters, due to its excellent thermal stability and resistance to thermal shock.

-

Foundry and Metallurgical Applications: R-SiC crucibles and refractory components are utilized in foundries and metallurgical processes where high temperatures, chemical resistance, and mechanical strength are required.

-

Semiconductor Industry: R-SiC is used in the production of wafer handling and processing tools, susceptors, and chambers for semiconductor manufacturing due to its thermal stability, chemical resistance, and electrical insulation properties.

-

Wear and Abrasion Applications: R-SiC is utilized in wear-resistant components, such as seals, bearings, and nozzles, in industries where high wear and abrasion resistance are crucial, including mining, oil and gas, and chemical processing.

-

Aerospace and Defense: R-SiC finds application in aerospace and defense sectors for components that require high-temperature resistance, lightweight construction, and superior mechanical properties, such as turbine blades, rocket nozzles, and heat shields.