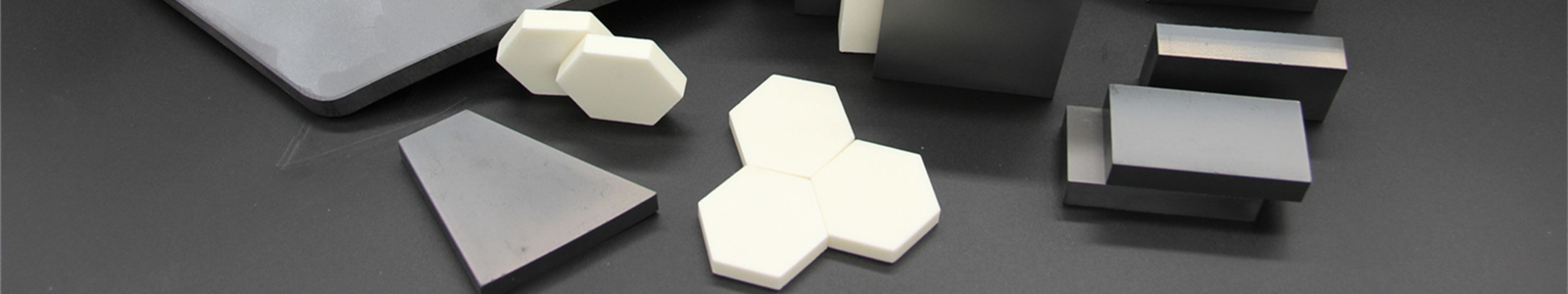

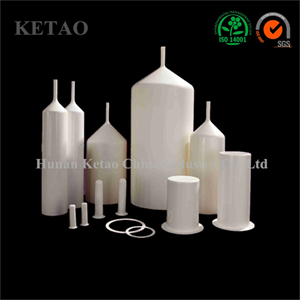

Boron carbide tiles are a type of ceramic armor designed to provide high levels of protection against various types of ballistic threats. They are typically used in body armor systems for military and law enforcement personnel, as well as in armored vehicles and aircraft. Boron carbide tiles are valued for their exceptional hardness, low density, and high strength-to-weight ratio.

Boron carbide tiles are often used in combination with other materials, such as Kevlar or Spectra, to create composite armor systems that offer even greater levels of protection. They are also used in structural applications that require high levels of wear resistance, such as cutting tools, nozzles, and grinding media.