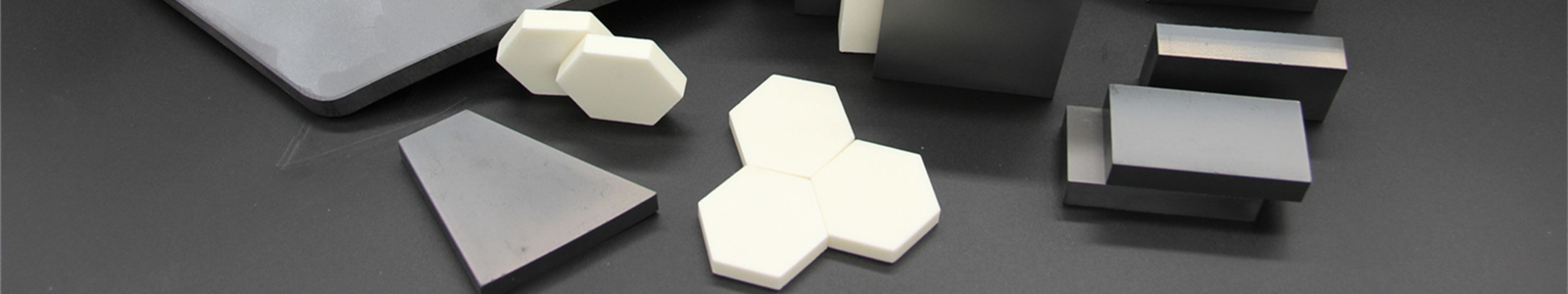

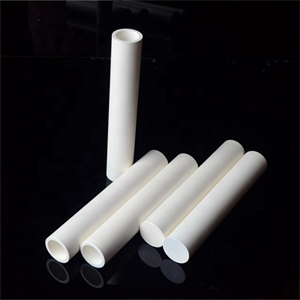

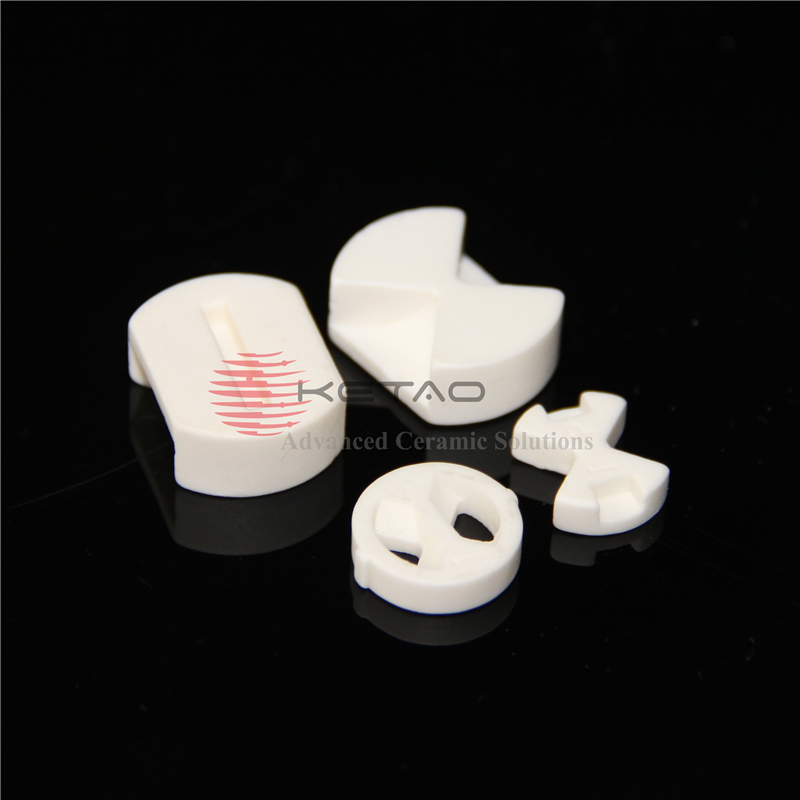

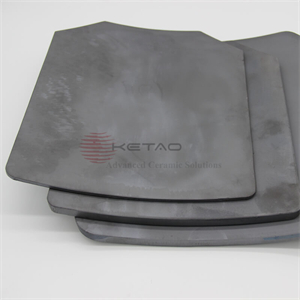

Material: Alumina

Crucible Shape : Arc/Cylindrical/Rectangle/Square/Cymbaeform

Type: Heat-Resistant Material

Refractorines: Refractoriness> 2000

Specification: 5ml 10ml 15ml 20ml 25ml 30ml 50ml 100ml 150ml 200ml-2500ml

High alumina purity:al2o3>99%,good corrosion resistance. 1600C in long use,1800C in short use.

Good thermal shock,no easy to crack.

Alumina ceramic crucible is a container made of alumina ceramic material that is resistant to high temperatures and thermal shock. It is commonly used in chemical laboratories for high-temperature applications, such as melting and analyzing metals, or for heating and evaporating liquids.