-

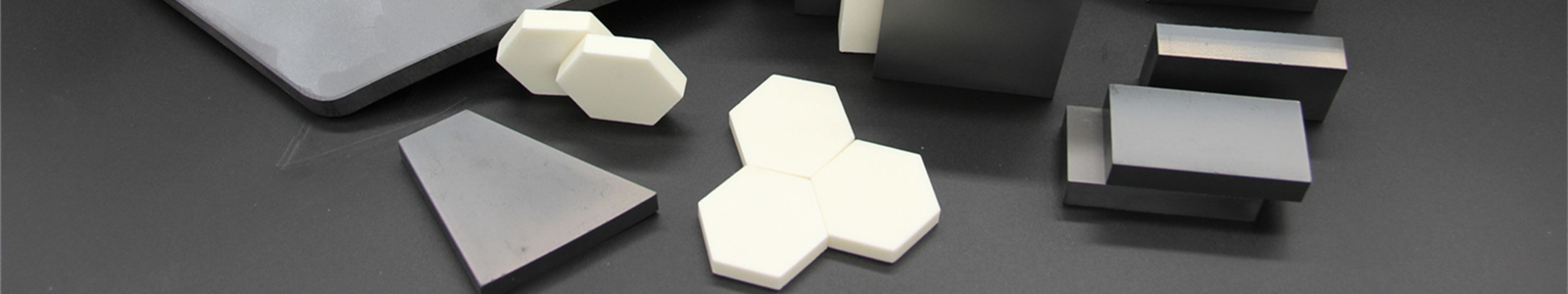

Superior Hardness and Wear Resistance: SSiC exhibits exceptional hardness and wear resistance, surpassing many other ceramic materials. It can withstand abrasive and erosive conditions, making it suitable for applications where durability is crucial.

-

High Strength and Mechanical Stability: SSiC possesses high mechanical strength and rigidity, allowing it to withstand high loads and maintain dimensional stability under extreme conditions. It can resist deformation and fractures, ensuring reliable performance in demanding applications.

-

Excellent Thermal Stability: SSiC has excellent thermal stability and can withstand high temperatures without significant degradation. It retains its mechanical properties and dimensional stability, making it ideal for applications in high-temperature environments.

-

Low Thermal Expansion: SSiC has a low coefficient of thermal expansion, which means it maintains its shape and dimensions even when exposed to rapid temperature changes. This property reduces the risk of thermal stress and improves overall reliability.

-

Corrosion and Chemical Resistance: SSiC has excellent resistance to corrosion and chemical attack, making it suitable for applications involving harsh chemicals, acids, alkalis, and corrosive environments. It provides long-lasting performance in challenging chemical processing applications.

-

Electrical Insulation: SSiC exhibits excellent electrical insulation properties, making it suitable for applications where electrical insulation is required alongside its other material properties. It is commonly used in electrical and electronic components.

-

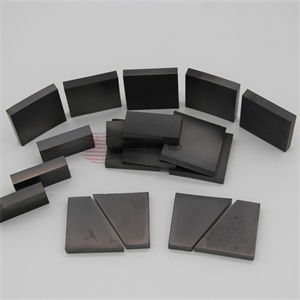

Mechanical and Industrial Applications: SSiC is widely used in mechanical and industrial applications that require high wear resistance, such as seals, bearings, pump components, and mechanical seals. It finds application in the automotive, aerospace, and manufacturing industries.

-

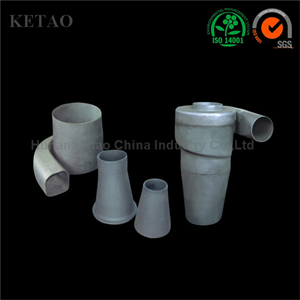

Chemical Processing: SSiC is utilized in chemical processing applications, including valves, pumps, and pipes, where resistance to corrosion and abrasion is critical. Its chemical stability and durability make it suitable for handling aggressive chemicals.

-

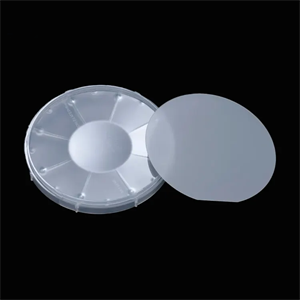

Semiconductor Industry: SSiC is used in the semiconductor industry for components such as wafer handling and processing, as well as in specialized equipment where high purity, thermal stability, and resistance to wear are required.

-

Energy and Power Generation: SSiC finds application in energy and power generation industries for components such as nozzles, impellers, and heat exchangers. Its high-temperature stability, wear resistance, and chemical inertness are advantageous in these applications.

-

Defense and Armor Systems: SSiC is utilized in defense applications, including armor systems and ballistic protection due to its exceptional hardness, strength, and resistance to penetration.

-

Electronics and Electrical Engineering: SSiC is used in electrical and electronic components that require high thermal conductivity, electrical insulation, and dimensional stability. Examples include ceramic substrates, heat sinks, and electronic packaging.