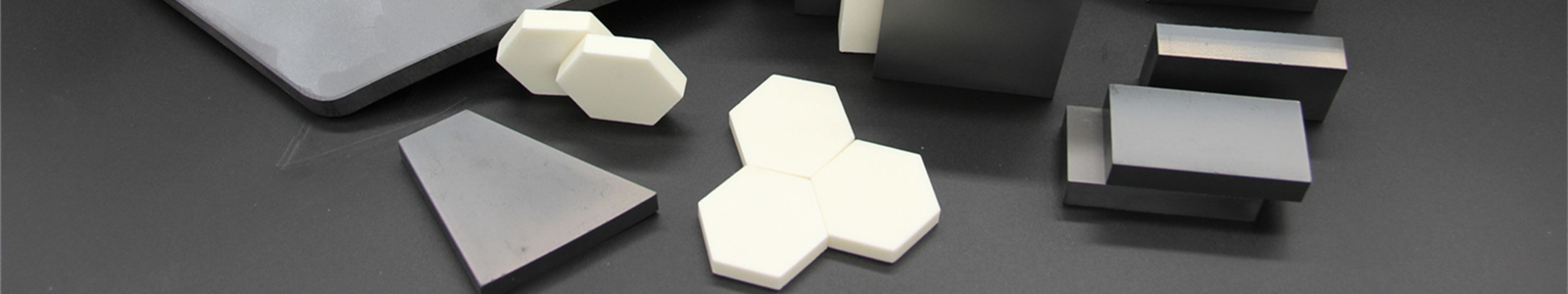

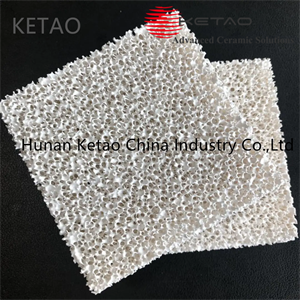

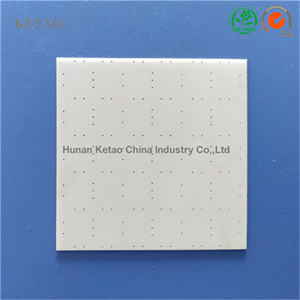

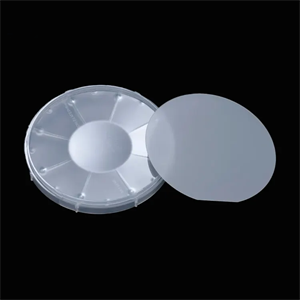

Alumina ceramic part refers to any component or part made from alumina ceramic material. Alumina ceramic is a type of ceramic material that is composed of aluminum oxide (Al2O3). It is a high-performance ceramic material known for its excellent mechanical properties, high wear resistance, and good thermal and electrical insulation.

Alumina ceramic parts can be used in a wide range of applications, such as in the semiconductor industry, medical devices, automotive parts, electronic components, and more. They are often used in high-temperature and high-wear environments due to their superior properties.