Mullite ceramics are a class of advanced materials known for their excellent combination of high temperature resistance, mechanical strength, and thermal shock resistance. Composed primarily of aluminum oxide (Al2O3) and silicon dioxide (SiO2), mullite ceramics possess a unique crystal structure that contributes to their exceptional properties and wide-ranging applications.

One of the key characteristics of mullite ceramics is their remarkable thermal stability. They can withstand extreme temperatures without undergoing significant structural changes, making them suitable for applications in high-temperature environments. Mullite ceramics exhibit a low coefficient of thermal expansion, allowing them to maintain dimensional stability even when exposed to rapid temperature changes. This property makes them valuable in industries such as aerospace, metallurgy, and kiln manufacturing.

In addition to their thermal stability, mullite ceramics possess excellent mechanical properties. They exhibit high strength, superior hardness, and exceptional resistance to deformation, making them suitable for applications requiring structural integrity and load-bearing capabilities. Mullite ceramics find use in the production of crucibles, kiln furniture, and refractory components, where their mechanical strength is essential in withstanding high temperatures and harsh operating conditions.

Mullite ceramics also exhibit excellent resistance to thermal shock. They can withstand rapid temperature variations without cracking or fracturing, making them suitable for applications that involve cyclic heating and cooling. This property is advantageous in industries such as glass manufacturing, where mullite ceramics are used as rollers, tubes, and thermocouple protection sheaths.

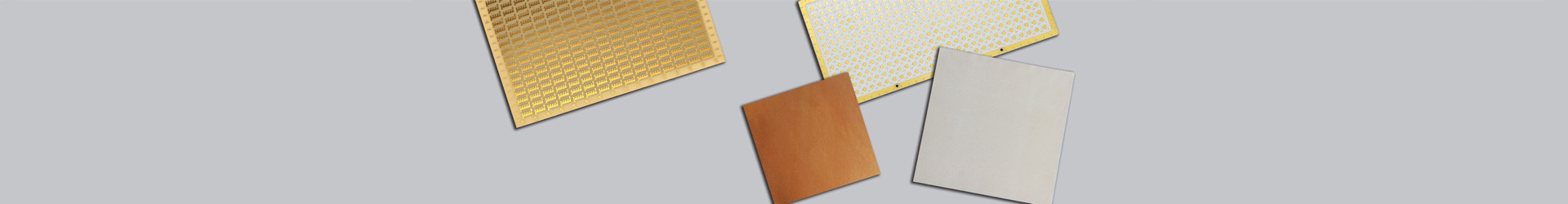

Furthermore, mullite ceramics offer good electrical insulation properties. They have a low dielectric constant and high electrical resistivity, making them suitable for use in electrical and electronic applications. Mullite ceramics find application in the production of insulators, circuit boards, and electrical components, benefiting from their ability to withstand high voltages and maintain electrical integrity.

The unique combination of thermal stability, mechanical strength, thermal shock resistance, and electrical insulation properties positions mullite ceramics as a versatile material in numerous industries. They are commonly used in the production of refractory products, kiln furniture, and high-temperature components in industries such as ceramics, glass, steel, and cement manufacturing.

As research and development efforts continue, advancements in mullite ceramic formulations and manufacturing techniques are expanding their range of applications. New compositions and processing methods are being explored to enhance their properties and address specific industry requirements.

Mullite ceramics offer exceptional thermal stability, mechanical strength, thermal shock resistance, and electrical insulation properties. Their versatility and reliability make them valuable in various industries where high temperature, mechanical durability, and thermal shock resistance are crucial. As technology advances, mullite ceramics are expected to play an increasingly significant role in demanding applications that require superior performance in harsh environments.