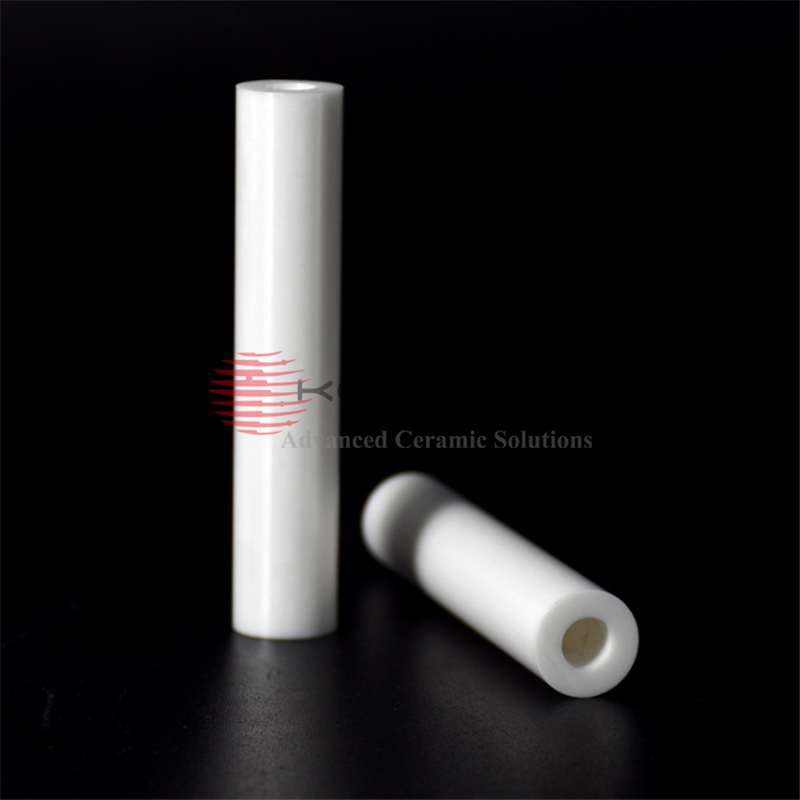

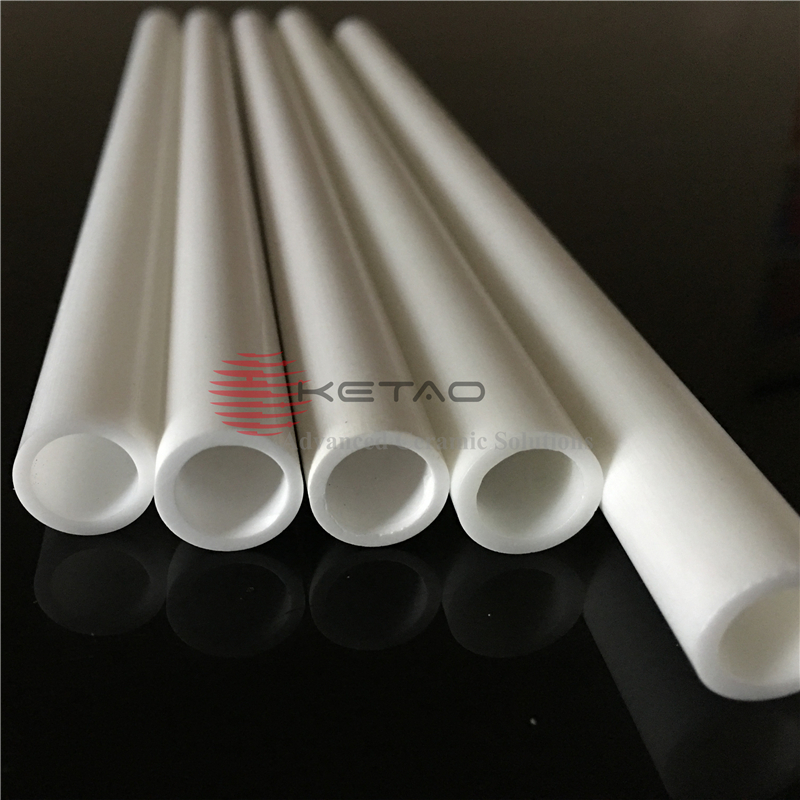

Boron carbide bushings are ceramic components made of boron carbide material. They are known for their exceptional wear resistance and high hardness, which makes them ideal for applications that involve sliding or rotating motions under high stress and extreme conditions. Boron carbide bushings are often used in industries such as aerospace, defense, automotive, and mining. They can be used as bearings, shafts, or sleeves in machinery and equipment, and can also be used in armor plating for personal and vehicle protection. The unique properties of boron carbide bushings make them a preferred choice for applications that require high strength, durability, and resistance to wear and corrosion.