Alumina ceramic rod is a type of ceramic product made from high-purity alumina materials through a series of manufacturing processes such as shaping, drying, and firing. The alumina content in these rods is typically greater than 95%, which gives them excellent mechanical, thermal, and electrical properties.

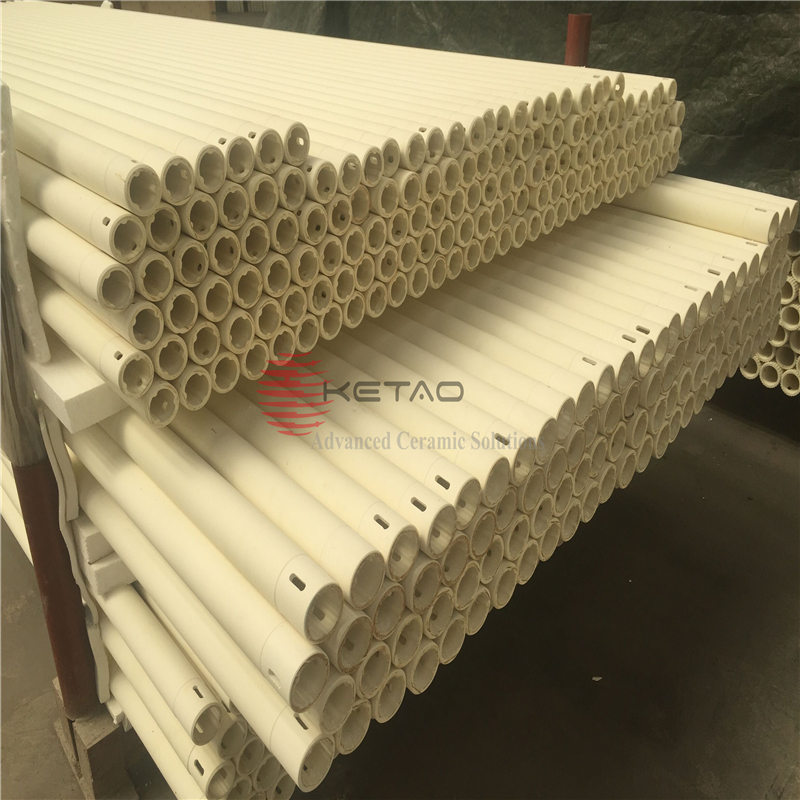

Alumina ceramic rods come in a variety of shapes and sizes, including round, square, and rectangular, and can be custom designed to meet specific requirements. They are often used in applications where high-temperature and wear resistance are critical, such as in the semiconductor, aerospace, and medical industries.

Alumina ceramic rods have a high melting point, making them ideal for use in high-temperature environments. They also have excellent hardness and wear resistance, making them resistant to scratching, abrasion, and corrosion. In addition, they have good electrical insulation properties, making them ideal for use in electrical and electronic applications.