- Home

- Product

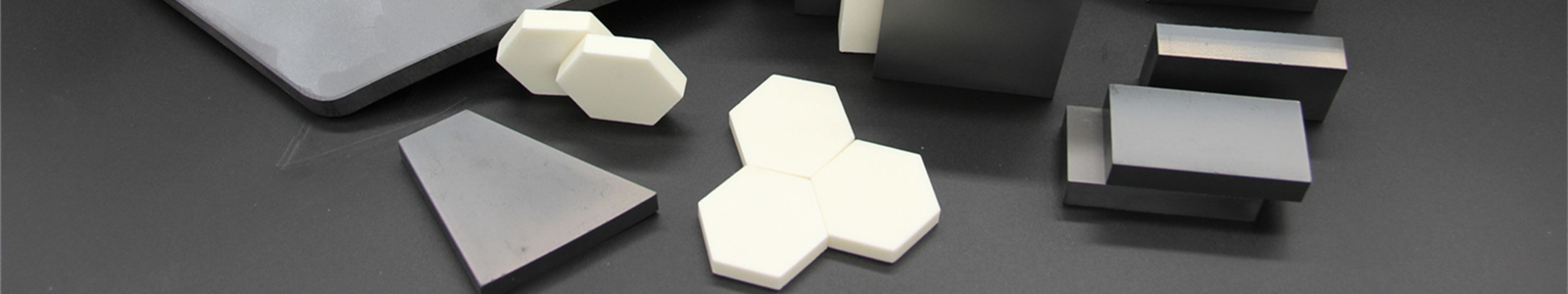

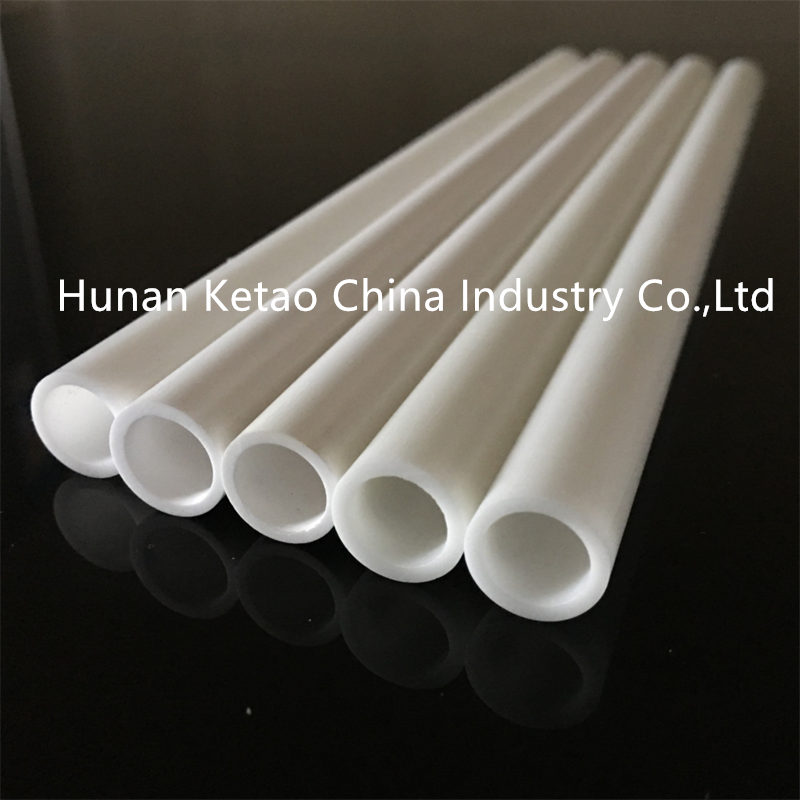

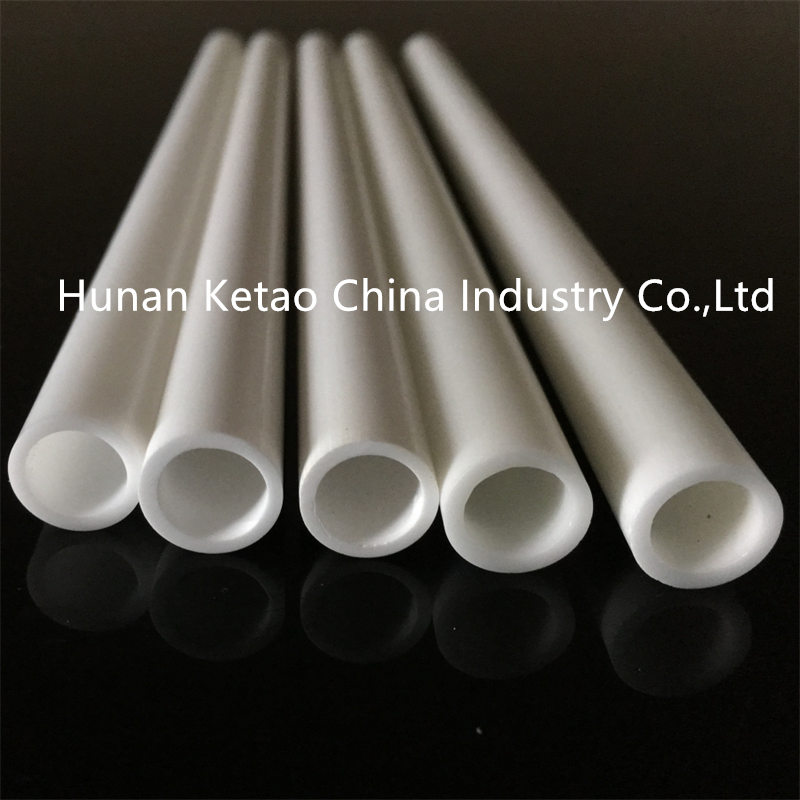

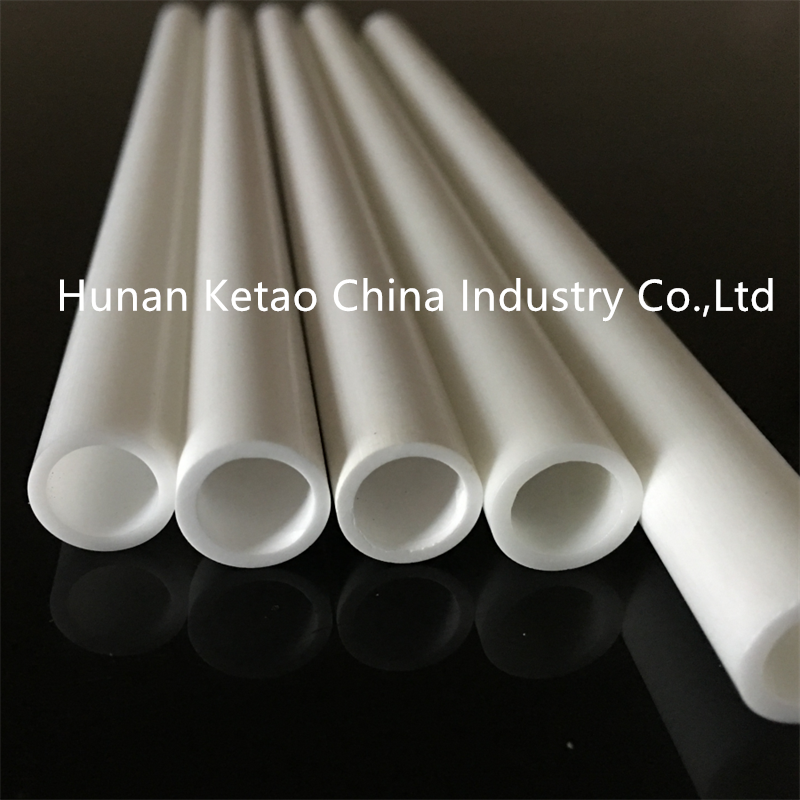

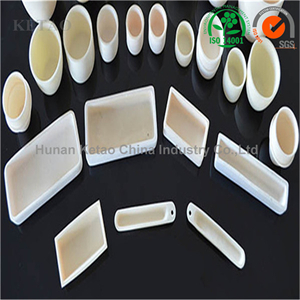

- Alumina Ceramics

- Alumina Ceramic Tube Alumina Ceramic Rod Alumina Ceramic Substrates Alumina Ceramic Disc Alumina Ceramic Plate Alumina Ceramic Roller Alumina Ceramic Crucible Alumina Ceramic Ring Alumina Ceramic Part

- Zirconia Ceramics

- Zirconia Ceramic Tube Zirconia Ceramic Rod Zirconia Ceramic Plate Zirconia Ceramic Disc Zirconia Ceramic Crucible Zirconia Ceramic Ring Zirconia Part Zirconia Knife

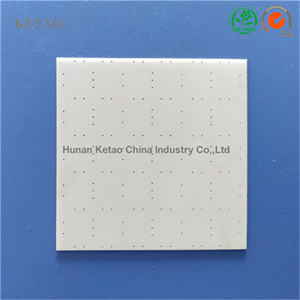

- Aluminum Nitride Ceramics

- Aluminum Nitride Substrates Aluminum Nitride Tube Aluminum Nitride Plate Aluminum Nitride Disc Aluminum Nitride Part

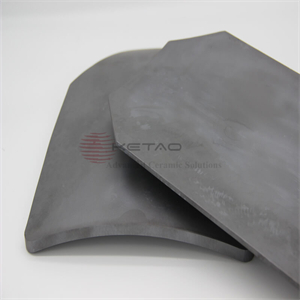

- Boron Carbide Ceramics

- Boron Carbide Tiles Boron Carbide Plate Boron Carbide Insert Boron Carbide Bushing Boron Carbide Tube Boron Carbide Nozzle Boron Carbide Ball

- Boron Nitride Ceramics (BN)

- Boron Nitride Tube Boron Nitride Plate Boron Nitride Ring Boron Nitride Nozzle Boron Nitride Crucible Boron Nitride Part

- Silicon Nitride (Si3N4) Ceramics

- Silicon Nitride Substrates Silicon Nitride Bearing Silicon Nitride Igniter Silicon Nitride Balls Silicon Nitride Tube Silicon Nitride Part

- About Us

- News

- Contact Us