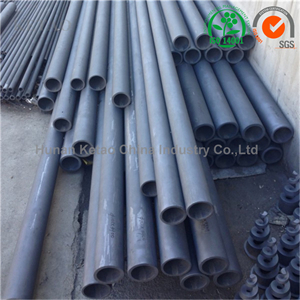

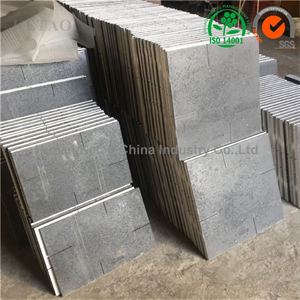

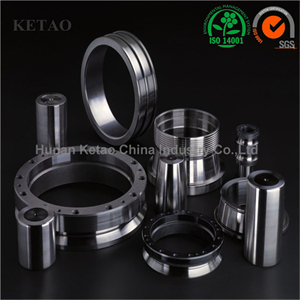

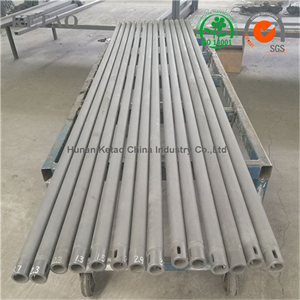

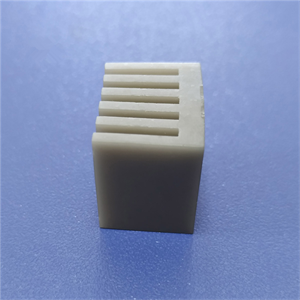

The name of the nozzle is: silicon carbide desulfurization nozzle, silicon carbide nozzle, silicon carbide nozzle, desulfurization nozzle, stainless steel nozzle, stainless steel nozzle.

Working temperature: 1380 centigrade;

Working pressure: 0.3-5Mpa;

Liquid medium: limestone slurry;

Connection mode: thread, bond, flange;

Specifications: 1/2 inches to 4 inches of various specifications;

Scope of application: environmental protection desulfurization and dust removal, spray tower, waste washing, fire prevention and fire fighting, gas cooling;

Advantages of sprinkler: reduce nozzle blockage and prolong service life effectively.