Silicon nitride (Si3N4) ceramics are a class of advanced materials renowned for their exceptional combination of high strength, excellent mechanical properties, and superior thermal stability. Composed primarily of silicon and nitrogen, silicon nitride ceramics have a unique crystal structure that contributes to their remarkable performance in demanding applications across various industries.

One of the key attributes of silicon nitride ceramics is their outstanding mechanical strength. They possess a high fracture toughness and flexural strength, allowing them to withstand significant mechanical stresses without fracturing. This inherent strength makes silicon nitride ceramics ideal for applications requiring structural integrity, such as cutting tools, bearings, and engine components.

In addition to their strength, silicon nitride ceramics exhibit excellent resistance to thermal shock and thermal stability. They can withstand rapid temperature changes without undergoing significant expansion or contraction, making them suitable for high-temperature applications. Their ability to maintain dimensional stability in extreme conditions is advantageous in industries like aerospace, where components must endure thermal cycling and rapid temperature fluctuations.

Silicon nitride ceramics also offer superior wear and corrosion resistance. Their hard and dense microstructure provides excellent resistance to abrasive wear, ensuring prolonged service life in harsh environments. Furthermore, their chemical inertness and resistance to corrosive substances make them suitable for use in chemical processing, semiconductor manufacturing, and automotive applications.

Another noteworthy characteristic of silicon nitride ceramics is their exceptional electrical insulation properties. They have a high dielectric strength and low electrical conductivity, enabling their use as electrical insulators in various applications. This property is particularly valuable in the electronics industry, where silicon nitride ceramics find application in high-voltage insulators, substrates, and packaging materials.

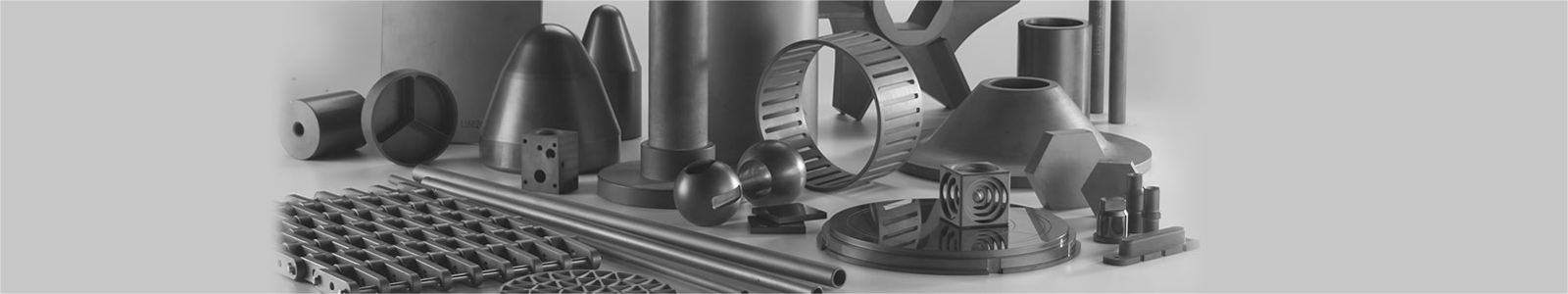

The unique combination of mechanical strength, thermal stability, wear resistance, and electrical insulation properties positions silicon nitride ceramics as a versatile material in multiple industries. They are extensively utilized in automotive and aerospace applications, including engine components, turbochargers, and bearings, where their high-temperature resistance and mechanical reliability are paramount.

Silicon nitride ceramics also find application in the semiconductor industry, serving as wafer handling and processing components due to their excellent thermal and electrical properties. Additionally, they are utilized in medical and dental fields for applications such as orthopedic implants and dental restorations, benefiting from their biocompatibility and wear resistance.

As research and development continue, advancements in silicon nitride ceramic manufacturing techniques and material compositions are driving further improvements in their performance. This opens up new possibilities for their application in emerging fields such as renewable energy, electronics, and advanced manufacturing.

Silicon nitride ceramics offer a unique combination of high strength, thermal stability, wear resistance, and electrical insulation properties. Their versatility and exceptional performance make them a valuable material in various industries, including automotive, aerospace, semiconductor, and medical. As technology advances, silicon nitride ceramics are poised to play an increasingly significant role in driving innovation and addressing the challenges of demanding applications.