Boron nitride ceramics, commonly referred to as BN ceramics, are a class of advanced materials known for their exceptional thermal stability, high electrical insulation, and excellent lubricating properties. Composed primarily of boron and nitrogen, boron nitride ceramics exhibit unique properties that make them highly valuable in various industries, including electronics, aerospace, and high-temperature applications.

One of the key characteristics of boron nitride ceramics is their exceptional thermal stability. They can withstand extreme temperatures without undergoing significant thermal expansion or deformation. Boron nitride ceramics have a high thermal conductivity, making them efficient heat dissipators. This property makes them suitable for use in high-temperature environments, such as furnace components, crucibles, and thermal management systems.

Boron nitride ceramics also possess excellent electrical insulation properties. They have a high breakdown voltage and low dielectric constant, making them effective insulators even at high temperatures. This electrical insulation property is crucial in applications where electrical conductivity must be minimized, such as in electronic devices and high-voltage applications.

Another notable property of boron nitride ceramics is their excellent lubricating capabilities. They exhibit low friction coefficients and high resistance to wear, making them suitable for use as solid lubricants in applications where high temperatures and extreme pressures are involved. Their self-lubricating properties contribute to reduced friction, increased component lifespan, and improved overall efficiency in mechanical systems.

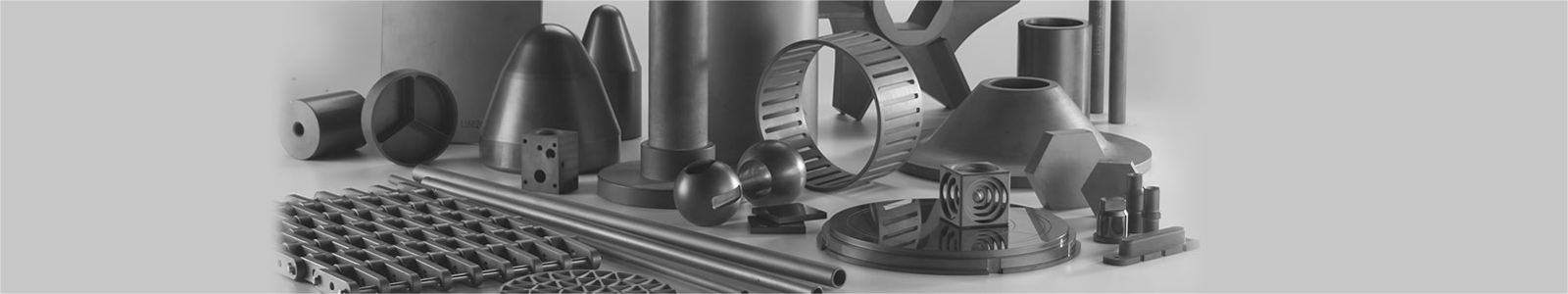

The unique combination of properties exhibited by boron nitride ceramics has led to their widespread use in various industries. In the electronics industry, they are employed as insulating substrates, heat sinks, and electrical insulators due to their excellent thermal and electrical insulation properties. Aerospace applications include use in rocket nozzles, heat shields, and thermal protection systems, where their high-temperature stability and insulation properties are highly valued.

In addition to electronics and aerospace, boron nitride ceramics find application in high-temperature environments such as metallurgical processes, where they serve as crucibles and furnace linings. They also have utility in the manufacturing of cutting tools, molds, and high-temperature coatings due to their exceptional thermal stability and lubricating properties.

Furthermore, boron nitride ceramics have emerged as potential materials for nanotechnology and biomedical applications. Their biocompatibility and thermal stability make them promising candidates for various biomedical devices, such as implants and drug delivery systems.

Boron nitride ceramics offer exceptional thermal stability, electrical insulation, and lubricating properties. Their applications span across industries, including electronics, aerospace, high-temperature environments, and emerging fields like nanotechnology and biomedicine. As research and development continue, boron nitride ceramics are expected to play an increasingly significant role in advancing technology and enabling new innovations in various sectors.