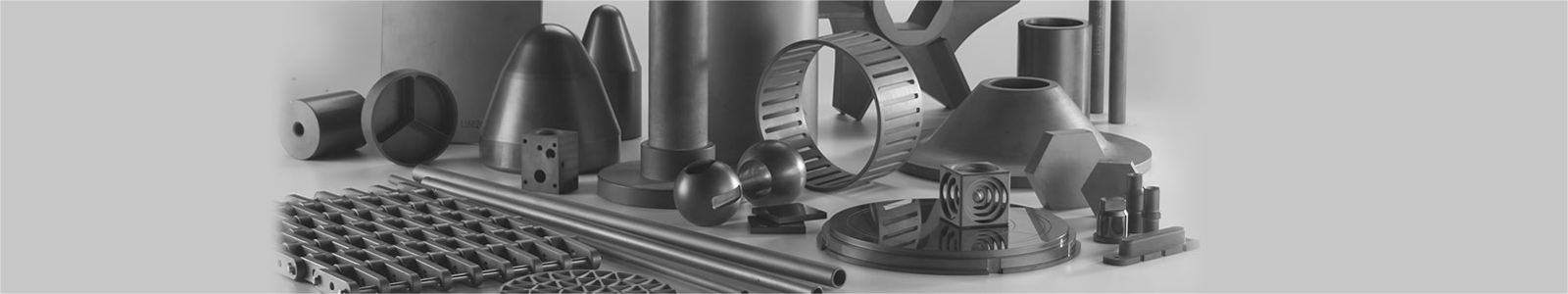

Alumina ceramics, also known as aluminum oxide ceramics, are a class of advanced ceramic materials with a wide range of applications. These ceramics are primarily composed of alumina (Al2O3), a compound known for its exceptional properties and versatility. Alumina ceramics are renowned for their excellent mechanical strength, high-temperature resistance, electrical insulation, and chemical stability. These remarkable characteristics make them a popular choice in various industries, including automotive, electronics, aerospace, medical, and chemical processing. In this introduction, we will provide an overview of alumina ceramics, highlighting their key features and discussing their significance in different fields.

Alumina ceramics exhibit exceptional mechanical strength, allowing them to withstand rigorous mechanical stresses and resist wear and tear. They have impressive tensile and compressive strength, making them suitable for applications where durability and reliability are critical.

One of the distinguishing properties of alumina ceramics is their remarkable resistance to high temperatures. They can withstand extreme thermal conditions without compromising their structural integrity, making them ideal for applications that involve elevated temperatures or rapid temperature changes.

In terms of electrical properties, alumina ceramics offer excellent electrical insulation. They possess a high dielectric strength and low electrical conductivity, making them effective insulating materials. This property is essential in applications where electrical insulation is required to prevent short circuits or unwanted electrical discharge.

Chemical stability is another notable characteristic of alumina ceramics. They exhibit resistance to corrosion from acids, alkalis, and other harsh chemicals, making them suitable for use in aggressive chemical environments. This property allows them to maintain their structural integrity and performance over extended periods.

Alumina ceramics find widespread applications in various industries. In the automotive sector, they are used in engine components, sensors, spark plug insulators, and catalytic converter substrates due to their high-temperature resistance and electrical insulation properties.

In the electronics industry, alumina ceramics are employed as substrates for electronic components, circuit boards, and semiconductor packaging. Their excellent electrical insulation and thermal conductivity properties make them vital for ensuring the reliable performance of electronic devices.

The aerospace industry utilizes alumina ceramics in jet engines, heat shields, and aerospace components due to their high-temperature resistance, mechanical strength, and lightweight nature. These ceramics contribute to improved efficiency and safety in aerospace applications.

Alumina ceramics also play a significant role in the medical field, where their biocompatibility and chemical stability make them suitable for use in orthopedic implants, dental prosthetics, and surgical instruments.

In the chemical processing industry, alumina ceramics are used in pumps, valves, and reaction vessels due to their excellent chemical resistance and durability. They help maintain the integrity of chemical processes and ensure safe and efficient operations.

In conclusion, alumina ceramics offer exceptional properties that make them valuable across a wide range of industries. Their mechanical strength, high-temperature resistance, electrical insulation, and chemical stability make them indispensable materials for applications where reliability, performance, and durability are paramount. As technology advances, alumina ceramics continue to find new and innovative applications, further solidifying their importance in various fields.